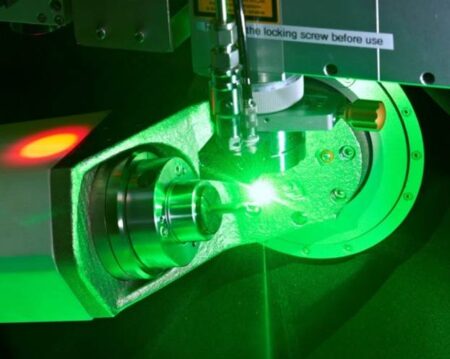

System offers fast and accurate laser machining solutions for the tool manufacturing industry.

Laser MicroJet (LMJ) systems are able to cut a wide range of materialssuch metals, ceramics, ultra-hard materials and carbide substrates as well as non-conductive materials such as SCD.

The laser cutting systems with 3 axes are ideal for

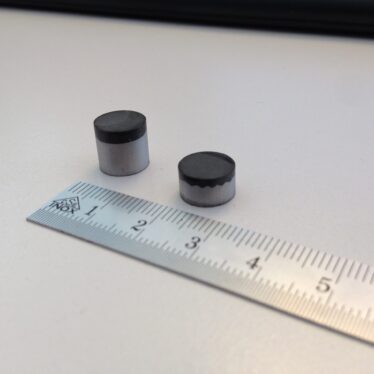

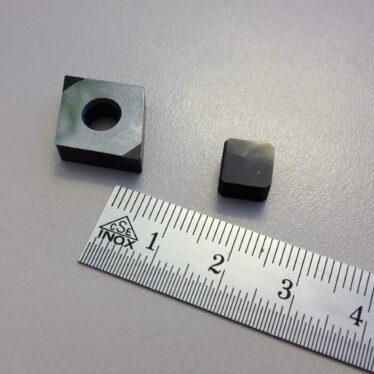

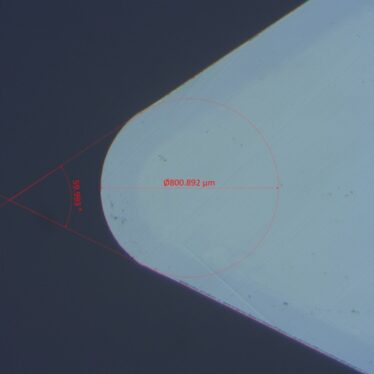

2D cutting, drilling, grooving or slicing of PCD, MCD, PcBN or CVD diamond tool bits, leaving, smooth cutting surfaces and sharp edges.

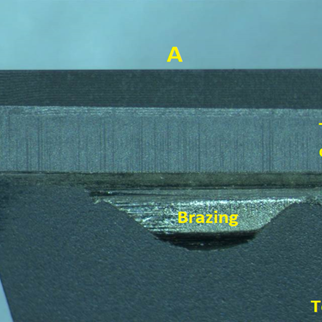

The 5-axis machines enable high-precision 3D ablation (shaping) for cutting single or multiple clearance angles and chamfering K-land edges. Furthermore, the LMJ technology allows homogeneous step-free cuts between diamond layer and carbide.