In the field of high precision and micro-machining of sensitive materials, stringent requirements for small and complex structures demand new processes: the water jet guided Laser MicroJet (LMJ) technology is the ideal solution.

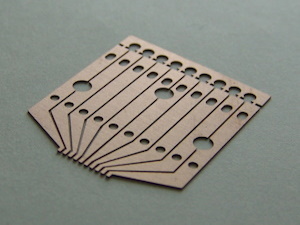

The hybrid LMJ method combines a laser with a hair-thin water jet that works as an optical fiber for guiding the laser beam. The cylindrical beam can be guided over a large working distance of up to 100 mm, enabling parallel high aspect ratio kerfs. Multi-thicknesses can be cut in one time; refocusing or distance control is not required. Holes can be drilled without taper.

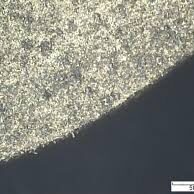

The water jet cools the work piece during laser ablation, enabling cold laser cutting, with no or very little thermal damage and negligible material changes, resulting in an exceptional high quality cut. At the same time, the water jet provides effective debris removal from the kerf, preventing contamination and burrs and leaving clean surfaces instead.

LMJ machines are flexible cutting systems for processing a wide range of materials, including “exotic” materials such as titanium, super alloys, ceramics, CMCs (Ceramic Matrix Composite). The liquid-guided laser technology also enables the processing of materials such as CuBe with low toxicity.

LMJ machines can be used for a variety of application fields, from Research & Development to customer services.