Systems with 3 or 5 axes are perfectly suited for machining high-precision parts in the energy and aviation industry.

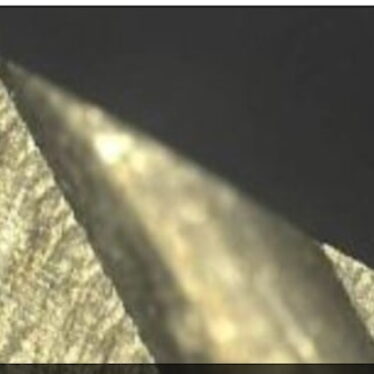

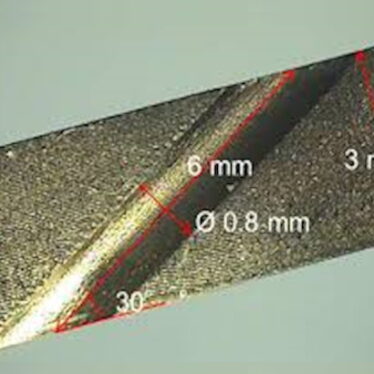

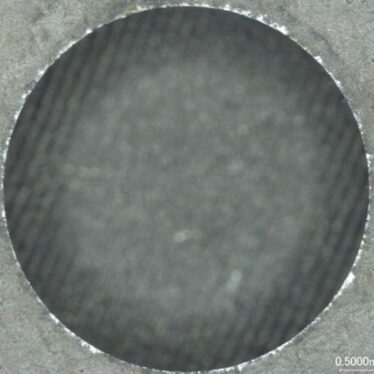

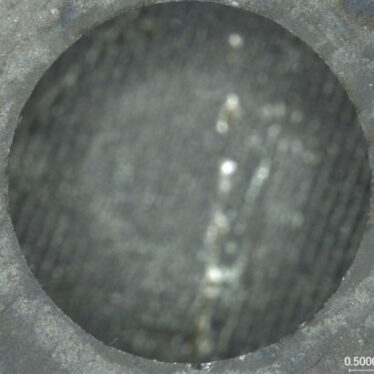

The hybrid water jet/ laser method provides precise through-hole drilling in hot section components of industrial gas turbines for cooling that require special materials such as thermal barrier coatings. Superalloys with or without thermal barrier coating can be processed in one simple step, without cracks or delamination in the ceramic coating and extremely low recast in the metal structure.

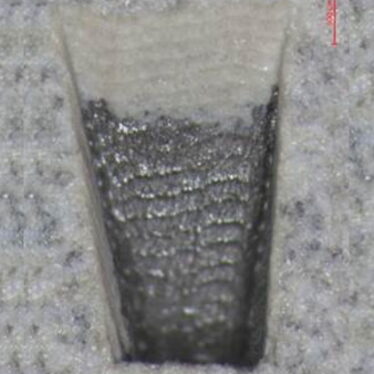

The LMJ systems are able to drill round and shaped holes (square, trapezoidal and inclined) at high process speed and with excellent quality at the entry and exit of the hole as well as on the sidewall.